-

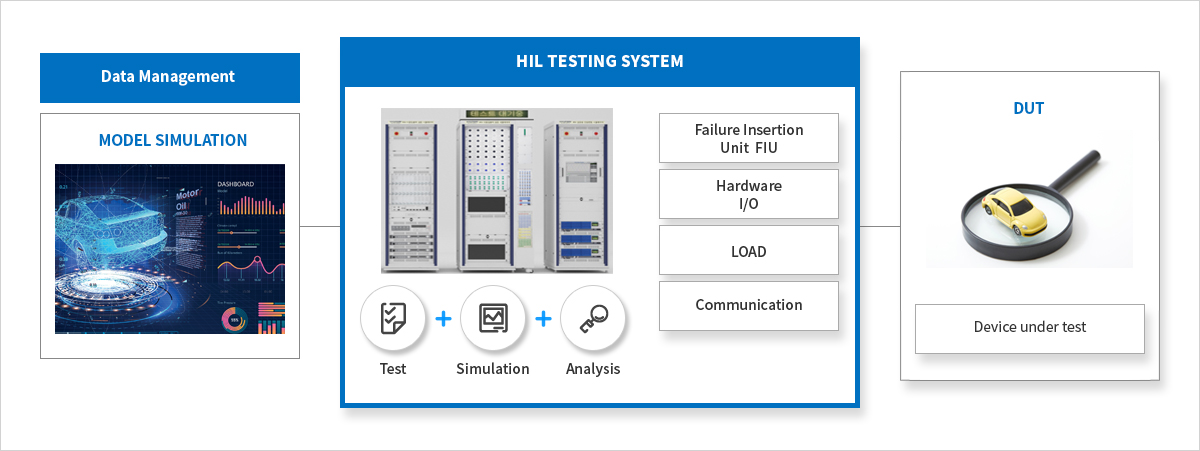

Hardware In the Loop (HIL) Testing Systems

- Verification of vehicle components (ECU and load)

- Vehicle communication bus control and evaluation

- Multi ECU system test

- Modular HIL Testing System

- NI PCI & PXI-based measurement technology

- Improved reliability and quality

- Reduced development costs and time

- Customized system INTERGRATION

- Scalable from small system to large system

Implementing a vehicle model in the HILS environment allows you to perform a network integration test under the same conditions as in actual driving in a virtual environment before actual vehicle testing. In addition to the functional tests, electrical failure such as disconnection or short circuit and fault diagnosis such as communication error can be simulated in real time. From the development stage, various scenarios and algorithms can be applied to automate the test, thus improving the quality and stability of the finished vehicle and contributing to reducing time and cost. In the era of autonomous vehicles, vehicle systems play a greater role than drivers. Therefore, it is necessary to build a virtual testing environment to verify these vehicle systems.

- HIL TESTING BENCH implementation (real case)

-

Using TEST BENCH allows you to secure the performance, stability and reliability of the system through repeated and FIU tests in various environments. By reducing the number of prototypes early in the costly development process, you can significantly reduce development costs and time. This is a very effective method to implement multiple tests (functions, diagnostics, FIUs, repetition) in the laboratory.

We know how to configure and simulate a test system in a virtual environment.

- HIL TESTING SYSTEM Composition & Verification Method

-

In order to verify the design, thorough and reliable testing is required.

-

STEP_01

Target selection

- - Controller selection and classification

- - Specification analysis

-

STEP_02

Environment building

- - Virtual environment building

- - HIL system connection

- - Load connection

-

STEP_03

Verification

- - Test case creation

- - Creation of automatic /

manual evaluation algorithms - - Verification (automatic / manual)

-

STEP_04

Analysis / Evaluation

- - Data acquisition and analysis

- - Correction, complementation

(hardware / software)

-

- Application Areas

-

It can be manufactured according to the system specifications, and the platform-based customized system is very easy to expand.

This system can be used for many applications, including complex simulations of virtual vehicles.Common Applications

ADAS(Advanced Driver Assistance System) Vehicle ECU verification (Engine, Powertrain, Chassis, Body, Multi-Media) Hybrid or Electric Motor Battery Management System Networked ECU Power Management System (PMS) Power electronics Research and educationMain Content

Analog and digital signal generation / instrumentation FAULT Simulation Multi ECU System Interlocking Test Support for automotive communication protocol

(CAN / CAN FD, LIN, Automotive Ethernet)) Actual load interlock test using real ECU Virtual driving performance evaluation in various environments ADAS Sensor and Radar System Test Power fluctuation test Sensor simulation Close-Loop Testing

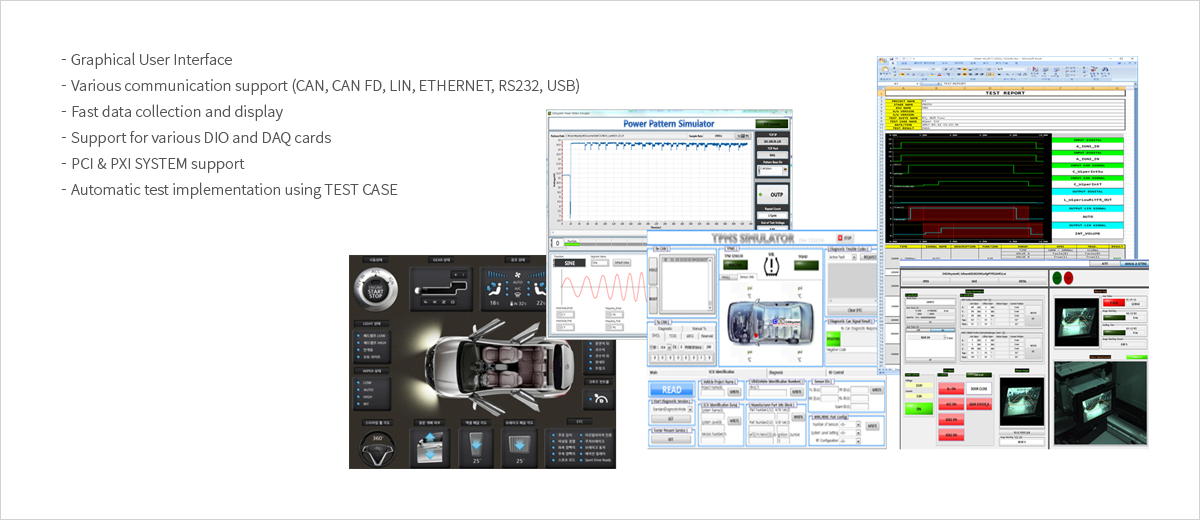

- Real-time simulation software

-

It provides a customizable graphical user interface by displaying, analyzing, and comparing waveforms collected from data acquisition, analysis, and monitoring systems. The software or firmware / algorithm / control systems are tested to simulate hardware components or test real components or physical systems.

- HIL TESTING SYSTEMS Implementation (Partner Solution)

-

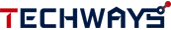

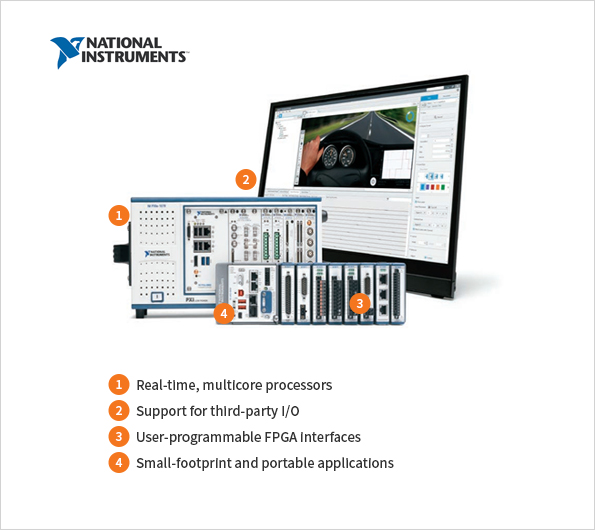

NI's HIL platform is a flexible, developmental platform (modular structure) which has excellent scalability, easily responding to system requirements.

High-speed data collection, real-time monitoring and analysis are easy, and you can easily control HILS with the LabVIEW user interface. Helping to conduct extensive testing early in development, it improves product quality while reducing overall development costs. Easy organic synchronization between many PXI instruments allows you to simulate scenarios and sensors. With FPGA technology, you can design test systems at very high loop speed.

-

- HIL TESTING SYSTEMS Implementation (Partner Solution)

-

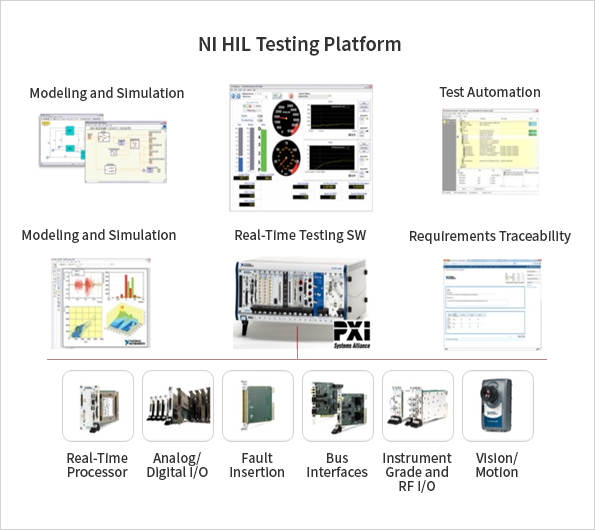

The Konrad Technologies ABex (Extension of Analog Bus for PXI) platform is a test solution that combines NI's LabVIEW and PXI platform.

The flexibility of the ABex PXI platform extension is used to efficiently share platform resources with customers, saving development time and costs. From single hardware and software modules to fully automated turnkey systems, we offer customized solutions to meet a wide range of customer requirements, providing customers with the services and technical knowledge to help them achieve their business goals.

-

- Efficient Development System

-

We provide efficient development solutions with flexible and scalable systems to meet customers’ requirements, product diversity and complexity.

-

Save Time

From the early stage of development, you can find errors in the product early through simulation and save time with automatic testing based on test scenarios. -

Extend

Based on the platform-based design, it can be integrated and easily upgraded according to users’ requirements. -

Reliability

By simulating the harsh conditions that are difficult to verify in actual vehicle testing, not only can the error be detected early but also iterative testing is also available, increasing the reliability of the test. -

Save Cost

Systematic and reliable testing can reduce the costs of product development by reducing the development stages. -

Efficient

development

system

-

Learn more for the test solution

-

Autonomous Driving

To make future vehicles a reality. We make our own test products for accurate testing for accident-free autonomous driving technology.

learn more

To make future vehicles a reality. We make our own test products for accurate testing for accident-free autonomous driving technology.

learn more

-

Eco-friendliness (EV,HEV, PHEV,FCEV)

Eco-driving technology which is environment-friendly, we complement our own technology for more accurate testing to provide competitive products.

learn more

Eco-driving technology which is environment-friendly, we complement our own technology for more accurate testing to provide competitive products.

learn more

-

Ethernet for cars

With automotive based Ethernet technology we are making specialized test products to increase the speed and stability of in-vehicle data communication.

learn more

With automotive based Ethernet technology we are making specialized test products to increase the speed and stability of in-vehicle data communication.

learn more

-

Electrical Units

We study and develop an optimal solution that allows you to more accurately measure the electric units and communication parts of your vehicle.

learn more

We study and develop an optimal solution that allows you to more accurately measure the electric units and communication parts of your vehicle.

learn more

-

Virtual driving environment simulation

In consideration of the various driving environments of the car, we are developing a professional solution that helps to conduct more accurate test through virtual simulation such as surrounding objects and road conditions.

learn more

In consideration of the various driving environments of the car, we are developing a professional solution that helps to conduct more accurate test through virtual simulation such as surrounding objects and road conditions.

learn more

-

NETWORK TEST

To validate the network appliance, we provide L2-3 Performance test(RFC-2544,RFC-2889), L4-7 Performance test(HTTP,HTTPS) and Security test(Attack, Malware) solutions.

learn more

To validate the network appliance, we provide L2-3 Performance test(RFC-2544,RFC-2889), L4-7 Performance test(HTTP,HTTPS) and Security test(Attack, Malware) solutions.

learn more

-

AP TEST SOLTUION (Wi-Fi)

We provide AP Performance Test solution including TR-398 and AP Functional Test solution such as Roaming test, Mesh test and so on for Wi-Fi Router.

learn more

We provide AP Performance Test solution including TR-398 and AP Functional Test solution such as Roaming test, Mesh test and so on for Wi-Fi Router.

learn more